Category

8 Motors Glass Beveling Straight Line Pencil Edge Grinding Polishing Machine

Professional Glass Machine Manufacturer, such as grinding machine, vacuum lifter, laminate furnace etc with competitive

Basic Info

| Grinding Head Number | 8 |

| Condition | New |

| Power | 13kw |

| Minimum Processing Size | 40*40mm |

| Maximum Glass Size | 1600*1600mm |

| Maximum Size with Extendable Platform | 2440*3000mm |

| Processing Thickness | 3-12mm |

| Max Bevel Surface Width | 25mm |

| Angle | 5-35degree |

| Weight | 1700kg |

| Speed | 0-4m/Min |

| Volt | 380V/50Hz |

| Wheels | 150*22(Bore)mm |

| Transport Package | Container |

| Specification | 3500*1100*1830mm |

| Origin | China |

| HS Code | 8464201000 |

| Production Capacity | 10000pieces/Year |

Product Description

Professional Glass Machine Manufacturer, such as grinding machine, vacuum lifter, laminate furnace etc with competitive price and good quality.

| Horizontal Beveling Machine | ||

| Technical Parameters | TYJT-G7 | TYJT-G8 |

| Dimensions | 3400*1000*1730mm | 3400*1000*1730mm |

| Net Weight | 1600kg | 1700kg |

| Glass Thickness | 3-10mm | 3-12mm |

| Angle | 5-35-degree | 5-35-degree |

| Max Bevel Surface Width | 25mm | 28mm |

| Mini Glass Size | 40*40mm | 40*40mm |

| Max Glass Size | 1600*1600 | 1600*1600 |

| Max Glass Size with Extension Tables | 2440*3000 | 2440*3000 |

| Speed | 0-4m/min | 0-4m/min |

| Voltage | 380V, 50HZ, 3 Phrase220V, 60HZ, 3 Phrase | 380V, 50HZ, 3 Phrase220V, 60HZ, 3 Phrase |

| Power | 13kw | 14.5kw |

| Number of the Motor Head | 7 | 8 |

Lay-out of the wheels:

| Position 1 | Position 2 | Position 3 | Position 4 | Position 5 | Position 6 | Position 7 |

| Diamond Wheel | Bottom Edge wheel | Resin Wheel | Resin Wheel | Resin Wheel | Felt Wheel | Felt Wheel |

| Position 1 | Position 2 | Position 3 | Position 4 | Position 5 | Position 6 | Position 7 | Position 8 |

| Diamond Wheel | Diamond Wheel | Bottom Edge wheel | Resin Wheel | Resin Wheel | Resin Wheel | Felt Wheel | Felt Wheel |

Finished Glass Effect:

Horizontal Type Glass Beveling Machine:

· Adopted synchronous belt conveying system, greatly improving precision· Composed of five major systems, which are control system, grinding system, clamping and conveying system, cooling system, and receiving system.

· The control system adopted an instrumental board showing the current and voltage, and operation is clear at a glance.· Grinding system equipped with high-speed three-phase AC motor and the design service life is up to 20 years. · Clamping transmission system: single worm gear speed change, AC frequency conversion speed control, glass running speed can be smoothly transitioned between 0-4 meters to meet different process requirements. The timing belt is made of imported Italian materials, and the surface adheres with PU and red glue, which reduces the damage rate of glasses during the clamping and transmission process and simultaneously ensures sufficient clamping force between the glass and the timing belt during operation. Relative sliding to ensure the accuracy of the grinding line.· Cooling system: adopted circulating water, double pump, and double tank cooling system. The polishing powder is added into one of the water tanks, which not only ensures the circulating cooling but also improves the polishing brightness.· Supporting system: The synchronous belt with the conveying system is used to avoid surface scratches during the operation of the glass. The control part and the working part organically cooperate to display the humanized design.

· Simple to operate, and its grinding accuracy is stable and continuous. It is widely used in home improvement glass, architectural glass, frameless glass and granite, stone plate, ceramic which thickness is within 20mm.

Vertical Type:

Other Items:

Company Profile:Founded by two metal equipment industry-leading companies in 2017, Qingdao Industry is specialized in developing the glass machine supplying business.Both our parent companies have more than 20 years of experience in the glass machine manufacturing industry, with excellent production capacity and outstanding quality control. Our factories cover a total area of 128, 608 square meters, with 500 technical staff, as well as 60 research and development engineers.Our mission is to provide"more reasonable price with the same quality, and same price with higher quality".

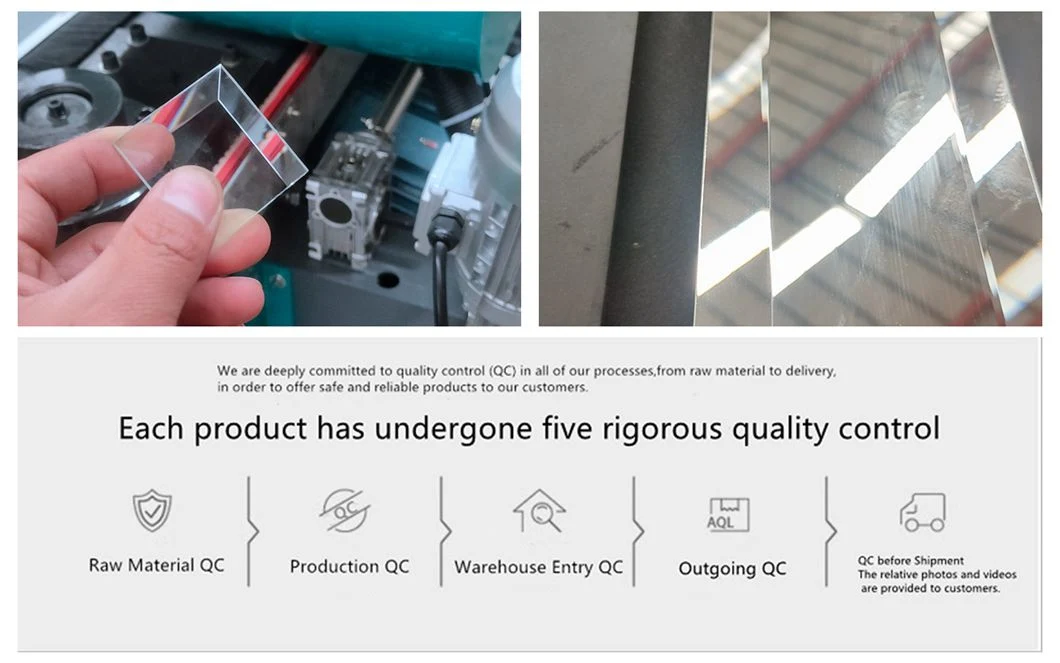

FAQ:1.Do you offer customized offers?Yes, we can accept custom.2.What's the delivery time?About 20 days.3.How can I get the after-sales services?We offer videos, pictures, and technical guidance immediately.4.How can customers buy parts once it break down?The lift adopts most of the common parts of hardware. You can buy the parts in your local hardware market or forklift parts shop.5.How can customers repair if any problem?One of the great advantages of the equipment is the very very low failure rate. Even it breaks down, we can guide to repair it by video and repair instruction.6.What's your QA&QC policy?3 times 100% inspection before shipping.

Previous: Stable Performance Pharmaceutical Glass /Plastic Vial Liquid Powder Filling Capping Sealing Production Line Automatic Vial Turnkey Plant Vial Making Machine

Next: Insulating Glass Machine Sealant Auto Sealing Robot Machine Double Glazing Glass Secondary for Glass Processing Company 10%off

Send inquiry

Send