Category

Double Glazing Press Production Line Automatic Insulating Glass Machine Insulating Glass Online Gas Filling

Double Glazing Glass Machinery Automatic Insulating Glass Production Line Window Glass Making Machine This production li

Basic Info

| Condition | New |

| After-sales Service | 30 Years |

| Color | Red, Blue |

| Size | Customed |

| Standard | CE, ISO |

| OEM | Supported |

| Transport Package | Custom |

| Specification | 1830*2440/2440*3660 |

| Trademark | Toyocc |

| Origin | Jinan, China |

| Production Capacity | 10000pieces/Year |

Product Description

Double Glazing Glass Machinery Automatic Insulating Glass Production Line Window Glass Making Machine

This production line is composed of 6 sections : feed section, washing and drying section, transition and storage section, light inspection section and spacer bar location section,inside flat press section, and storage section.

Main Feature:

- Achieve the functions of inside assembly,automatically fill argon gas.

- Adopts the PLC to control the working condition and touch screen

- Automatic detect coated surface of coating glass and Low-E glass

- Air knife can automatic adjust according to glass thickness.

- Brushes' rotate speed variable frequency drive.

- Aluminum spacer and glass automatic positioning system

- It has remote monitor and program upgrade functions.

- Can produce double, triple,low-e, and laminated insulating glass.

- Automatic detect the length and height of glass, automatic adjust the best gas filling time.

- Automatic gas filling press machine adopt servo motors, which has assembling, pressing and automatic gas filling functions. Ensure the insulating glass argon gas concentrate ≥ 90%

Technical parameter:

| Power Supply | 380V/50HZ 37.5Kw |

| Dimension(LxWxH) | 21300x2800x3800mm |

| Production quantity | 600-700 IG units/8hs |

| Max Glass Size | 2500x3500mm |

| Min Glass Size | 300x400mm |

| Washing Glass Thickness | 3-20mm |

| Washing Glass Speed | 0-10m/min |

| Insulating Glass Thickness | ≤60mm |

| Transmission Glass Speed | 45m/min |

| Compressed Air | 0.8m³/min |

| Air Pressure: | 1Mpa |

| Environment temperature | 7-50ºC |

Structure and Function for Each Part

--Brief introduction:

Adopt PLC control the working condition, this production line can produce Low-e glass, double glazing, triple glazing. Which include 6 sections, that is feeding section., washing and drying section, storage section, light inspection section and spacer bar put section, press and inside assembly section with argon gas ,output section

-- operation methods:

There are two operation methods in the control panel: "automatic 'and ^manual If the separate operation of each section or maintenance is needed, the 'manual 'operation method is needed.

Secotion 1: Feed Section

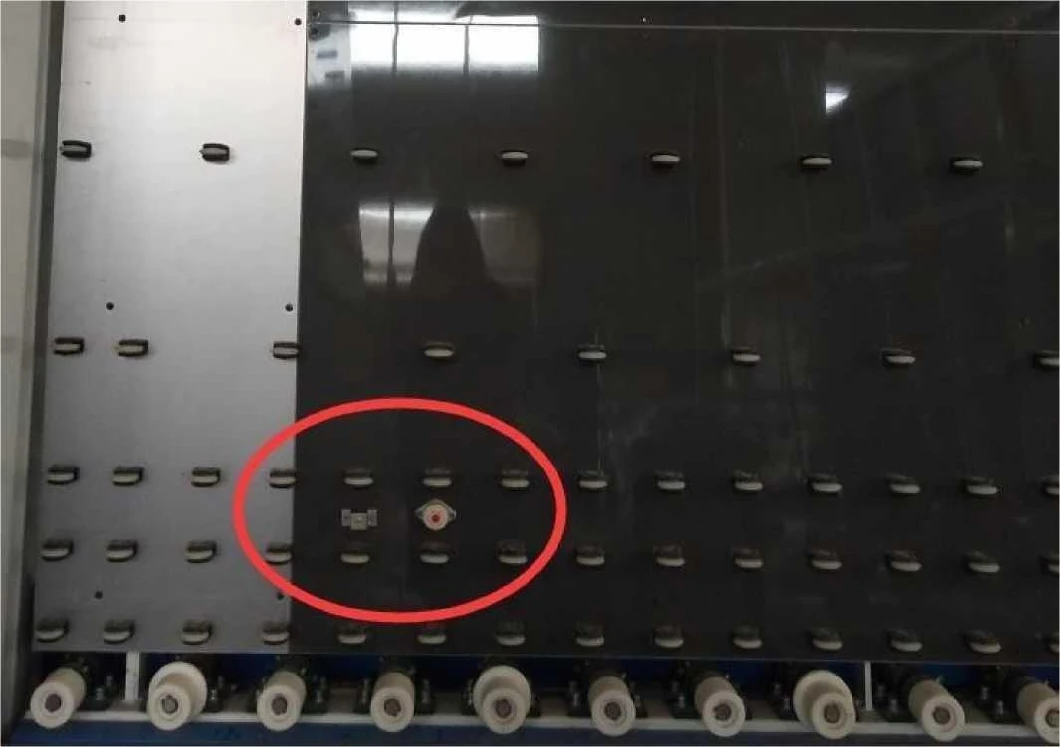

It is the first section of the line and its main function is to transmit the glass to the washing and drying section. The glass panels are made of high density board which can resist the moisture.The transmission wheels are made of polyurethane which can resist abrasion and corrosion. And the transmission wheels can be used with both sides. So it can save the material cost.there is one low-e coating checking system, if you put glass on the wrong side, it will give an alarm.

Section 2: Washing and Drying Section part:

Section 3 & Section 4

Transition and Storage Section

light inspection section and spacer bar location section

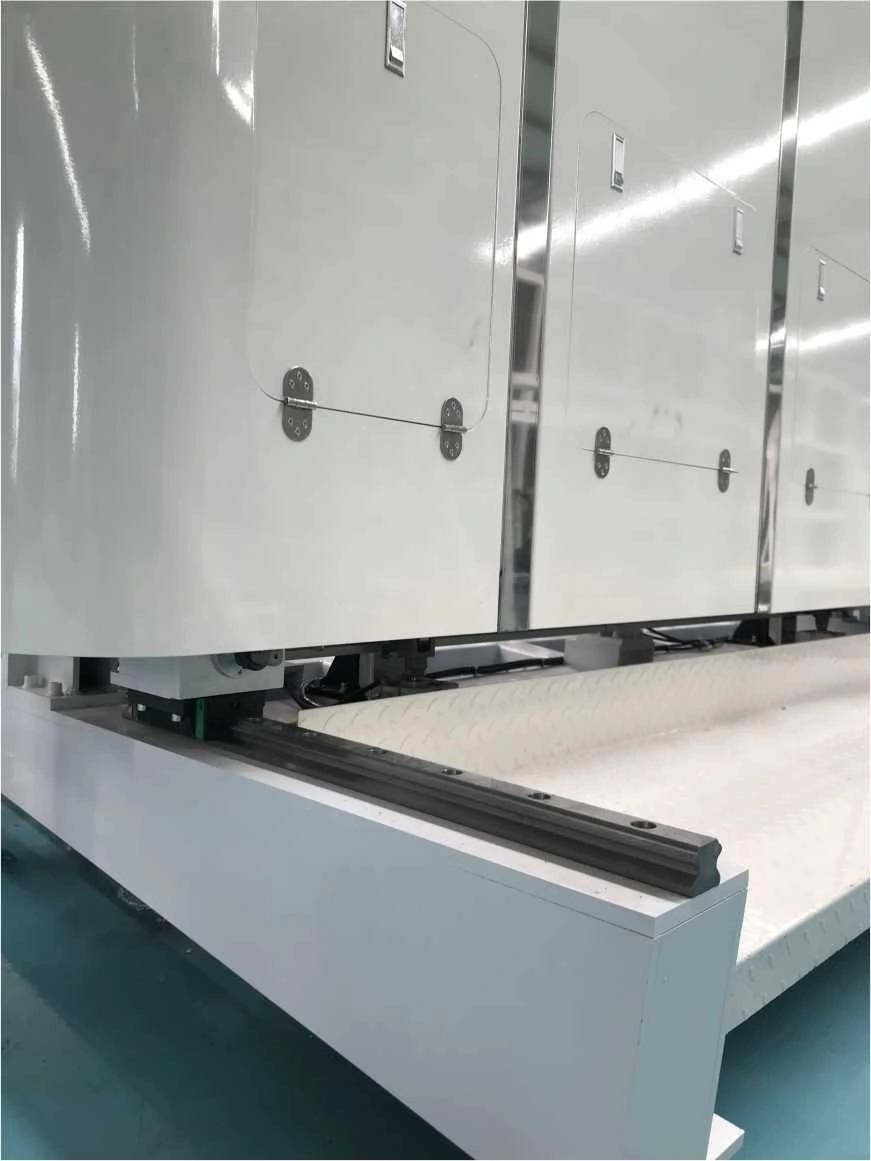

Section 5. Inside Flat press and assembly section

Section6. Transition and Storage Section

Qingdao TOYOCC Industry is jointly funded by two metal equipment industry leading companies in 2017. We focus on developing the international market and international business.Both our parent companies have more than 20 years of experience in manufacturing industry, including long-term international foundry production.With excellent production power, research and development and outstanding quality control, our factories cover a total area of 128, 608 square meters, have 500 technical staff, as well as 60 research and development engineers.Our factories have been granted TS16949, ISO9001 international quality system certification, Germany CE certification and ISO14001, T28001 management system certification.The factories owns world-class production line and imported mould, and introduced various patented products to the market.Supported by our parent companies' superb manufacturing ability, Qingdao Toyocc Indsutry is dedicated in expanding its international cooperation and promoting the concept of manufactured in China and the created in China.At the same time, we provide quality products and services for factories, traders and direct users across the globe.Our credo is "excellent price with same quality, and same price with high quality", with this in mind we seek win-win cooperation with our parterners.Currently, we are seeking for tier one agents all over the world and expanding our bilateral business in import and export to develop cross-border electronic commerce.We would like to give our warm welcome to product users, distributors and platform website, to work together and achieve mutual win-win.